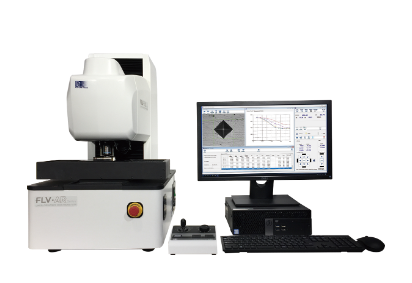

FLV-AR SERIES

Innovative lifting head and wide test load range are adopted. Advanced intelligent high-speed sample profiling function system. Improved high speed, high precision, excellent operability, reading efficiency and repeatability. Reliable hardness test as close as human eyes and sensitivity.

DISTANCE AND ANGLE MEASUREMENT FUNCTION

Just click between two points to measure the distance and click on three points to measure the angle easily. (ARS・ARS-F)

IMAGE OF THE PROFILING FUNCTION

The original position set is very simple using this function to recognize a sample shape automatically. (ARS・ARS-F)

REPORT GRAPH

Measurement data can be saved in CSV format and transferred to an original report. (Common to each model)

LOAD CELL TYPE LOADING MECHANISM

Large, heavy samples and multiple samples can be set up at once.

The work table does not require a hole for the lifting screw and there is no need to choose the place to install the tester.

HIGH RESOLUTION CAMERA

Equipped with a 1.3M pixel high resolution digital camera.

SAMPLE SURFACE INCLINE/SLOPE CORRECTION FUNCTION

The Z axis will be controlled along with the surface tilt by selecting the 3 position angle adjustment. This function is to improve the accuracy of load application and measurement position. Also, to shorten the autofocus time and avoid accidental contact of the sample and the lens/indenter. (Built-in safety device).

MEASUREMENT IMAGE SAVE FUNCTION

The measured indentation image can be checked quickly. Edit data easily and quickly by remeasuring the saved image.

LARGE MOTORIZED XY STAGE

Great built-in stage. It can avoid the tilting of the stage that will be created with a large and heavy sample, and realizes highly accurate loading application.

It's also quiet. It is possible to move the stage to the center by double clicking and to move the stage finely by dragging it.

It is easy to align the original position of the sample and can dramatically shorten the setting time.

VARIOUS MEASUREMENT PATTERNS

Fully automated test cycle (indentation, measurement, data recording) by selection of measurement pattern.

Random measurement combined with sample profiling function and measurement function that tracks the edge of the sample as a standard feature.

FUNCTION THAT PLOTS THE SAMPLE BORDER AS A STANDARD FUNCTION

Straight・Zigzag・Circle・Arc・Set of lines・Random・Array・Teaching, etc. We will satisfy the needs of users.

IMAGE PROCESSING SOFTWARE

The ability to read unclear indentations on the mirrorless surface has been improved by more advanced image processing software.

VARIOUS DATA OUTPUT FORMATS AND STATISTICAL PROCESSING

To measure case hardening/induction hardening, the depth of the selected hardness case will be displayed and recorded in the table once the multiple measurement is completed. Multiple measurement data, hardness table, case depth, max. value, min Value, mean value, dispersion, standard deviation, OK-NG criteria, conversion data, etc.

Multiple data outputs must be available. Display and output of a color profile image linked to hardness values are standard features.

Excel data transfer function. The test result will be exported to the original report form.